By Levi | 17 February 2022 | 0 Comments

What Is Screening Efficiency?

Screening efficiency is an indicator of the work quality of the screen, indicating the degree to which the screening operation is carried out and the quality of the screened product. The screening efficiency is usually expressed as the ratio of the mass of the under-screen product obtained during screening to the mass of the particle fraction smaller than the screen size contained in the raw material and expressed as a percentage. The ideal screening efficiency is that the particles smaller than the screen hole can pass through the screen hole and enter the screen to become the undersize; while the particles larger than the screen hole remain on the screen and become the oversize. The actual screening efficiency cannot reach the ideal state, and there is always a part of the under-screen material still remaining on the screen, resulting in incomplete screening. Therefore, the screening efficiency reflects the completeness of screening, that is, the quality of screening.

Theoretically speaking, all the fine particles in the screening objects whose particle size is smaller than the screen size should pass through the screen to become the under-screen product, while the coarse particles larger than the screen size should all be left on the screen and discharged into the over-screen product. However, in fact, due to the influence of various factors in the screening process, there will always be some fine particles smaller than the screen holes left on the screen and discharged together with the coarse particles to become the products on the screen, and the products on the screen that do not pass through the screen holes The more fine particles, the worse the screening effect. In order to evaluate the separation efficiency of screening equipment, the index of screening efficiency is introduced.

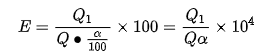

The screening efficiency refers to the ratio of the quality of the product under the screen actually obtained to the quality of the fine-grained material smaller than the screen size contained in the screend objects, expressed as a percentage, namely

In the formula, E is the screening efficiency (%); Q is the quality of the screening objects entering the screen; Q1 is the quality of the product under the screen; α is the fine particle content (%) of the screening objects entering the screen smaller than the screen hole.

Theoretically speaking, all the fine particles in the screening objects whose particle size is smaller than the screen size should pass through the screen to become the under-screen product, while the coarse particles larger than the screen size should all be left on the screen and discharged into the over-screen product. However, in fact, due to the influence of various factors in the screening process, there will always be some fine particles smaller than the screen holes left on the screen and discharged together with the coarse particles to become the products on the screen, and the products on the screen that do not pass through the screen holes The more fine particles, the worse the screening effect. In order to evaluate the separation efficiency of screening equipment, the index of screening efficiency is introduced.

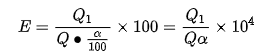

The screening efficiency refers to the ratio of the quality of the product under the screen actually obtained to the quality of the fine-grained material smaller than the screen size contained in the screend objects, expressed as a percentage, namely

In the formula, E is the screening efficiency (%); Q is the quality of the screening objects entering the screen; Q1 is the quality of the product under the screen; α is the fine particle content (%) of the screening objects entering the screen smaller than the screen hole.

Leave a Reply

Your email address will not be published.Required fields are marked. *